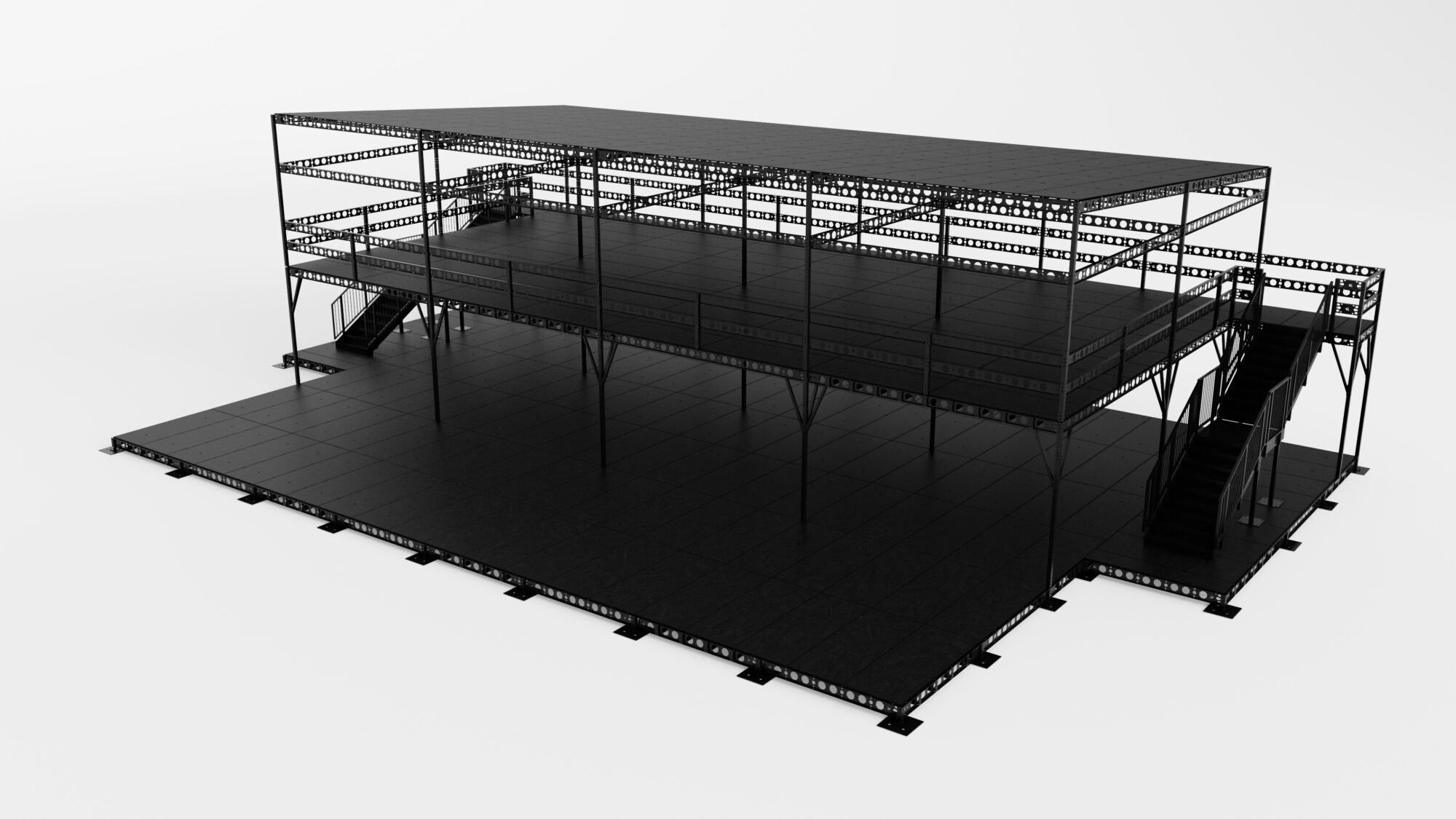

Our Modular Structures

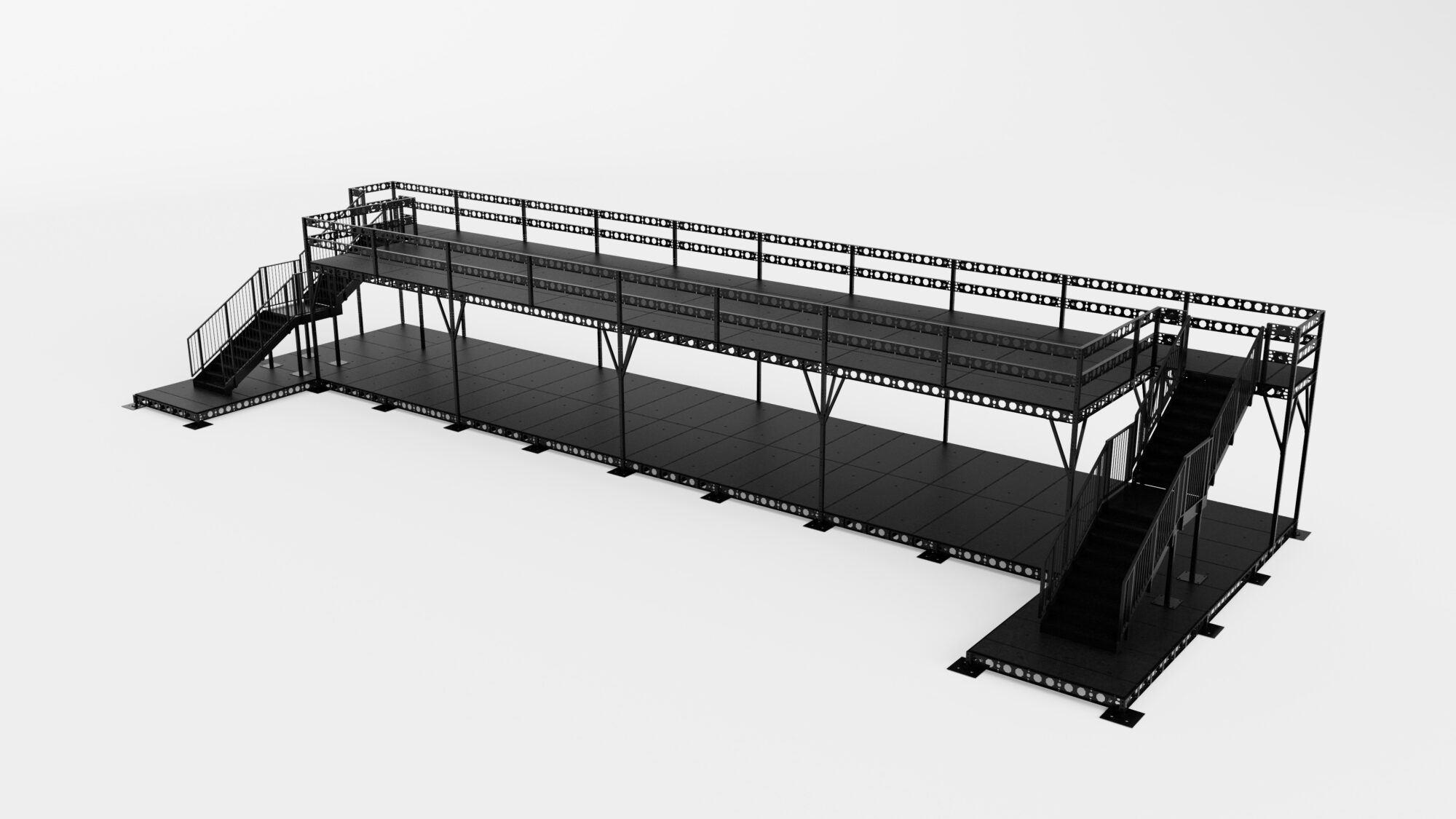

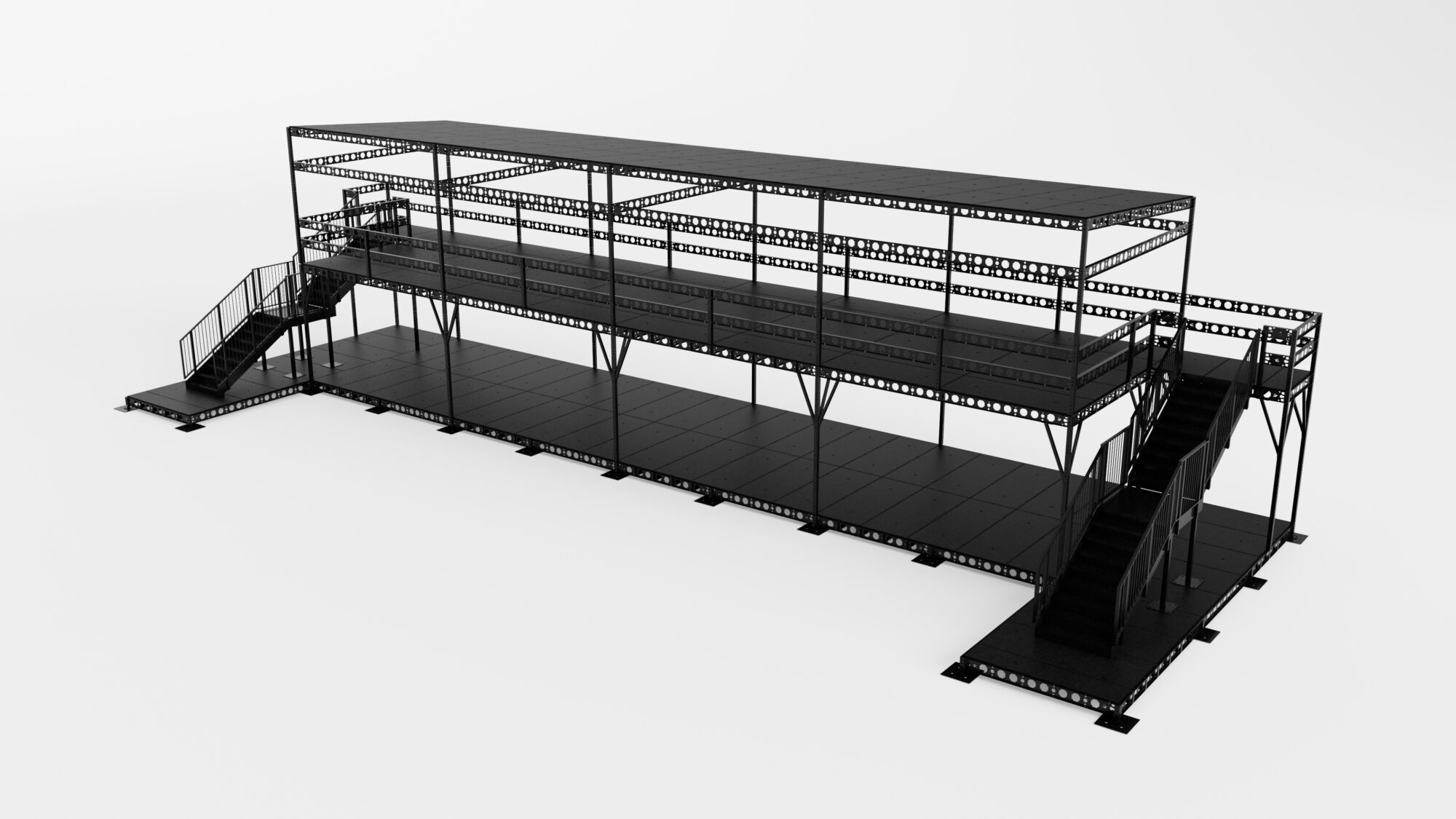

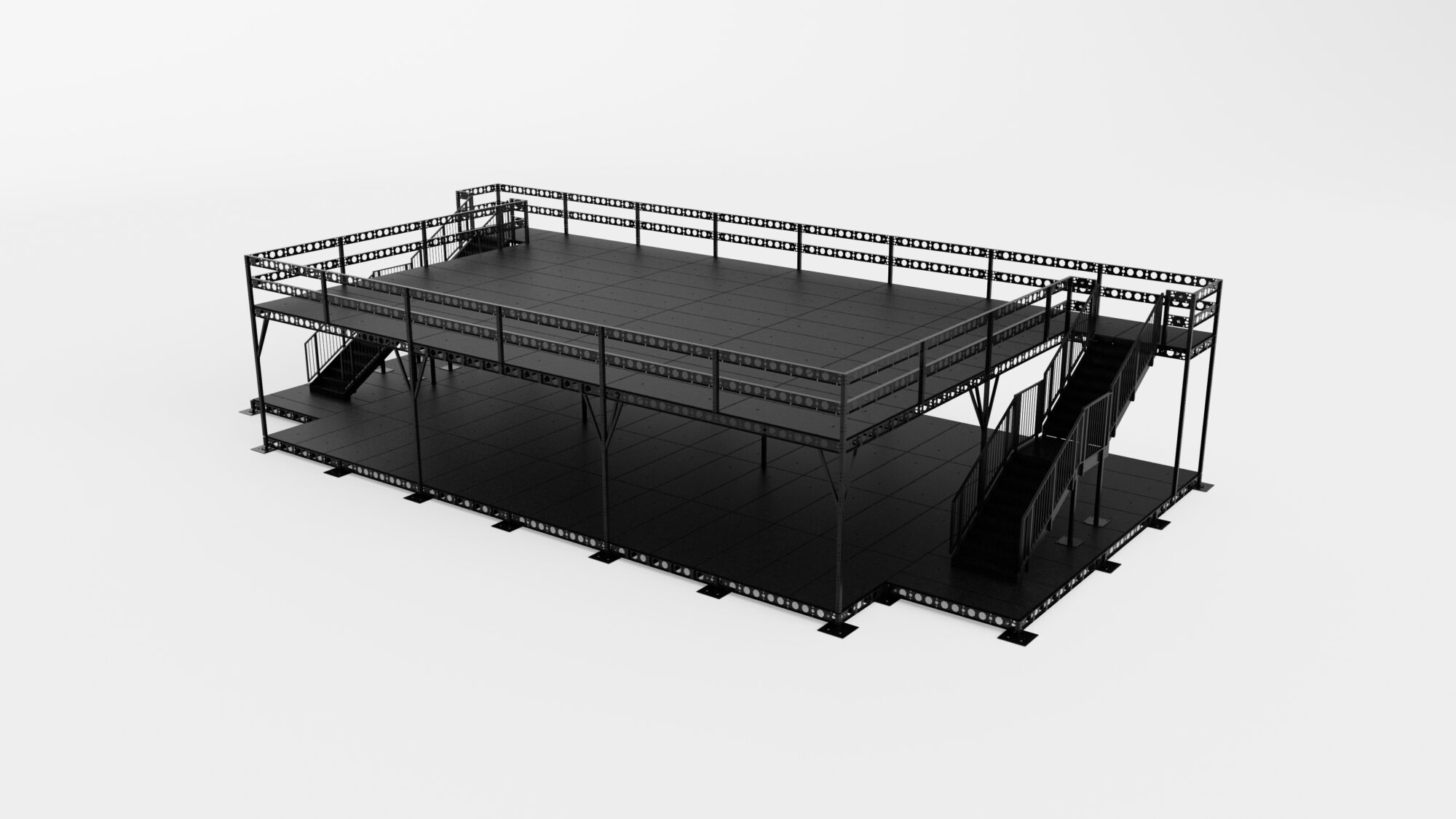

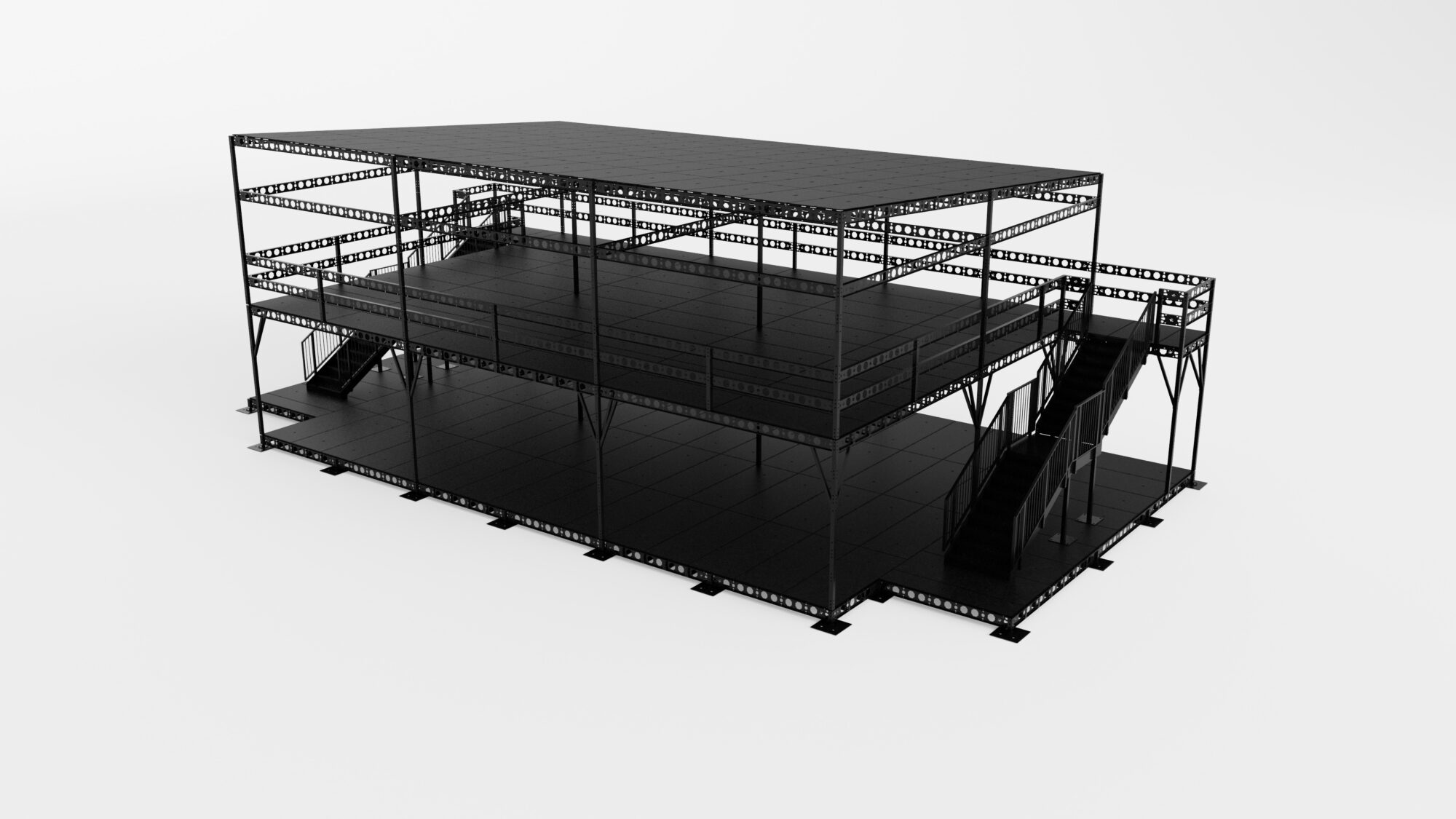

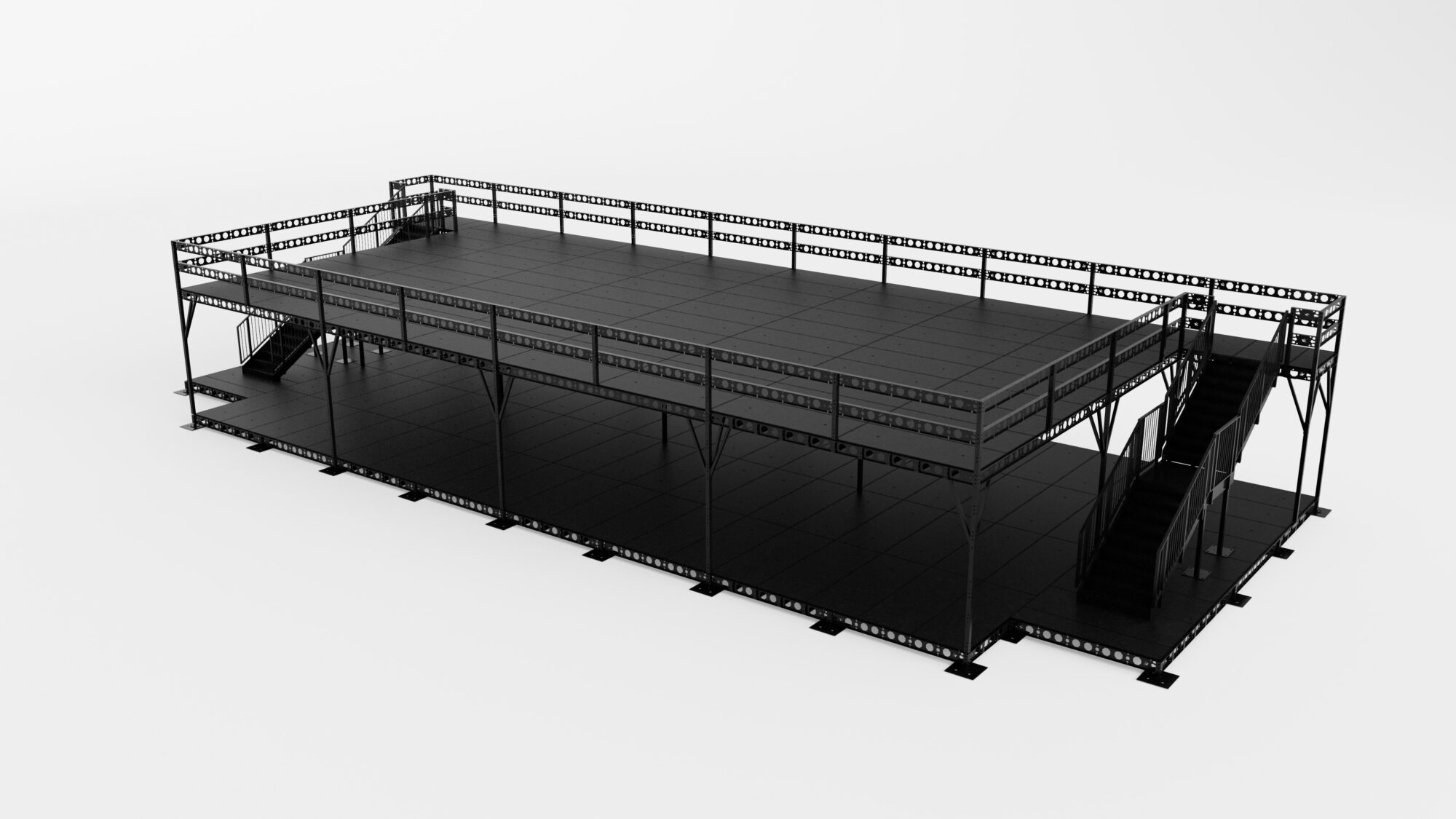

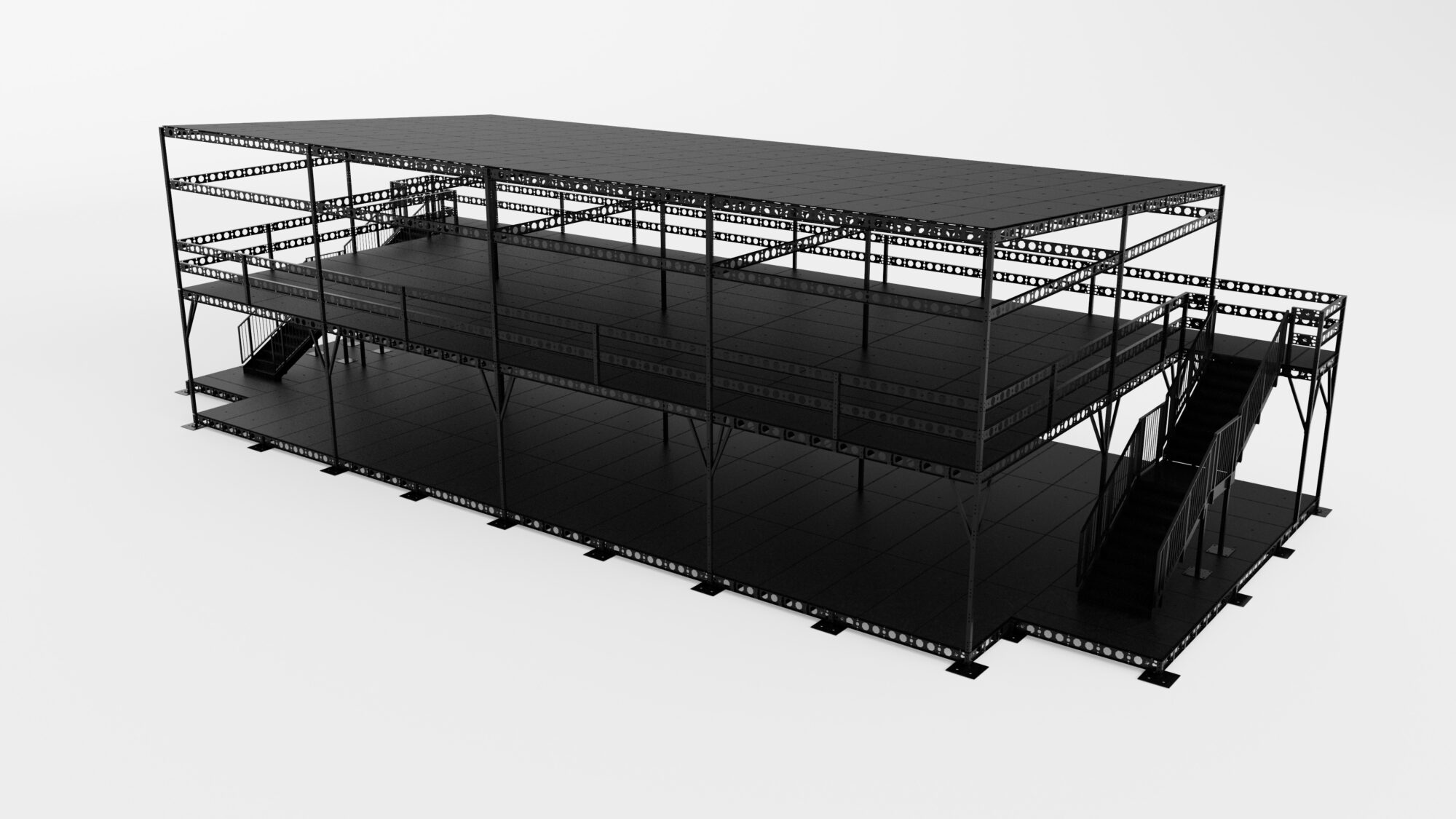

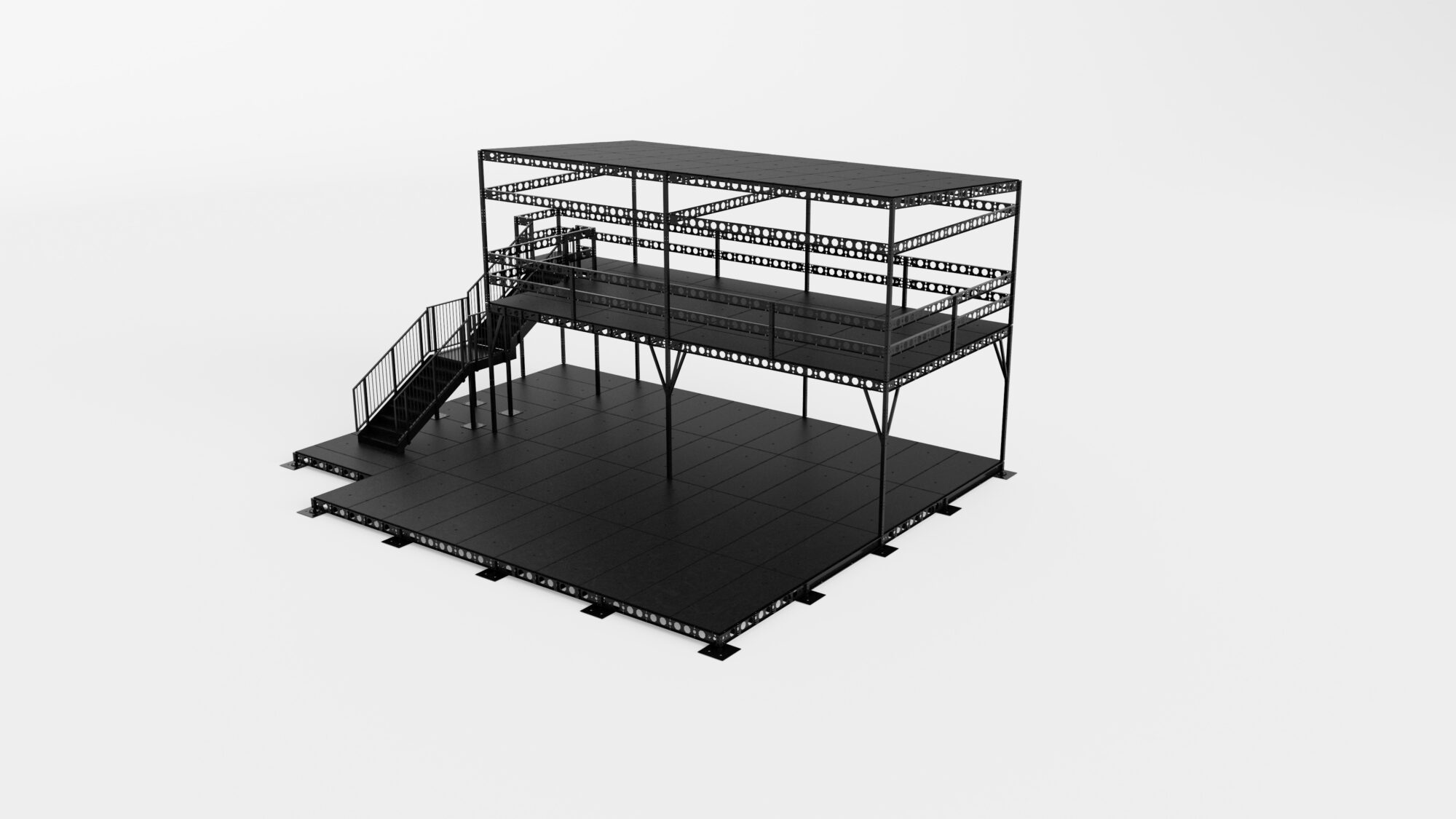

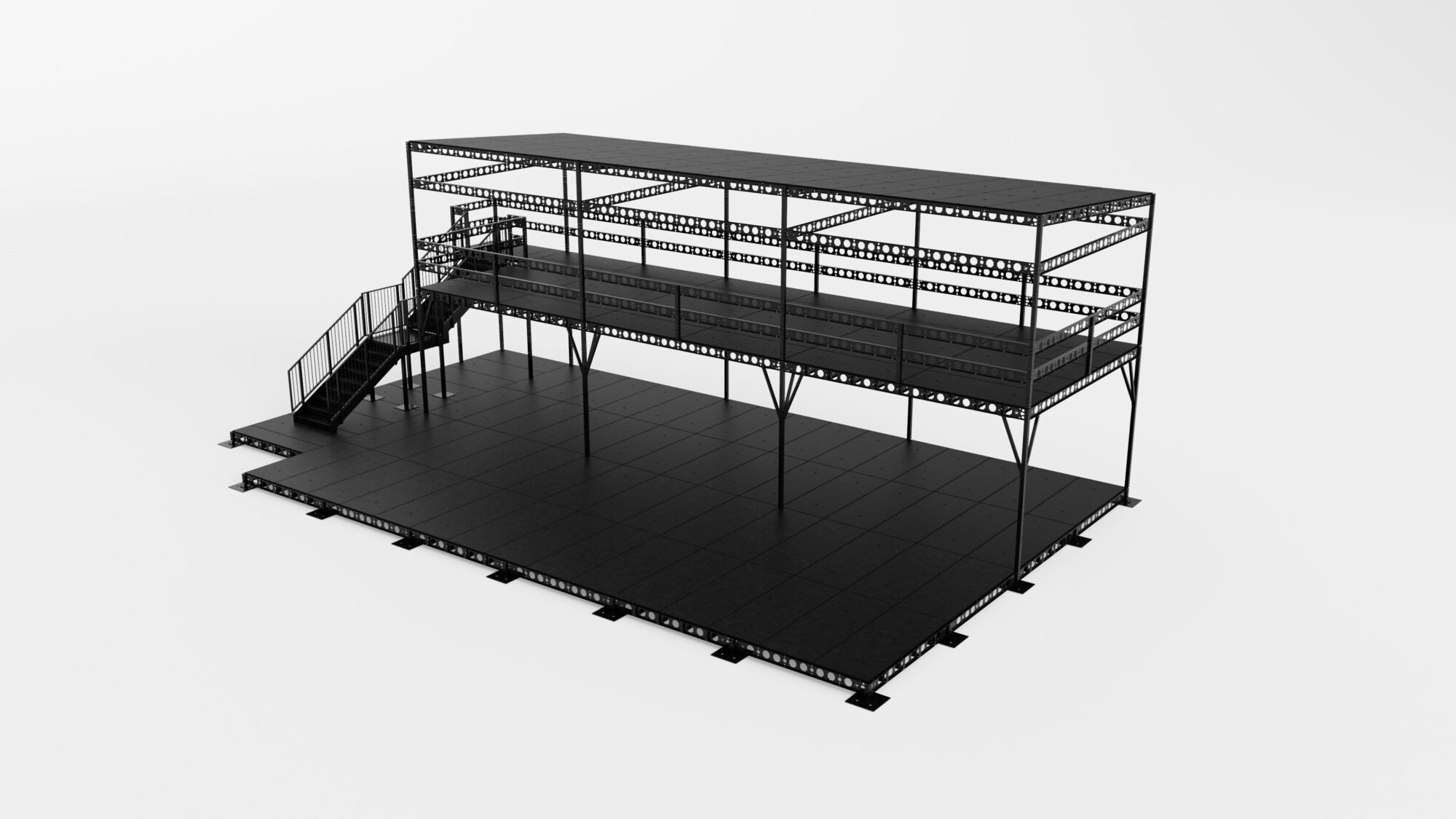

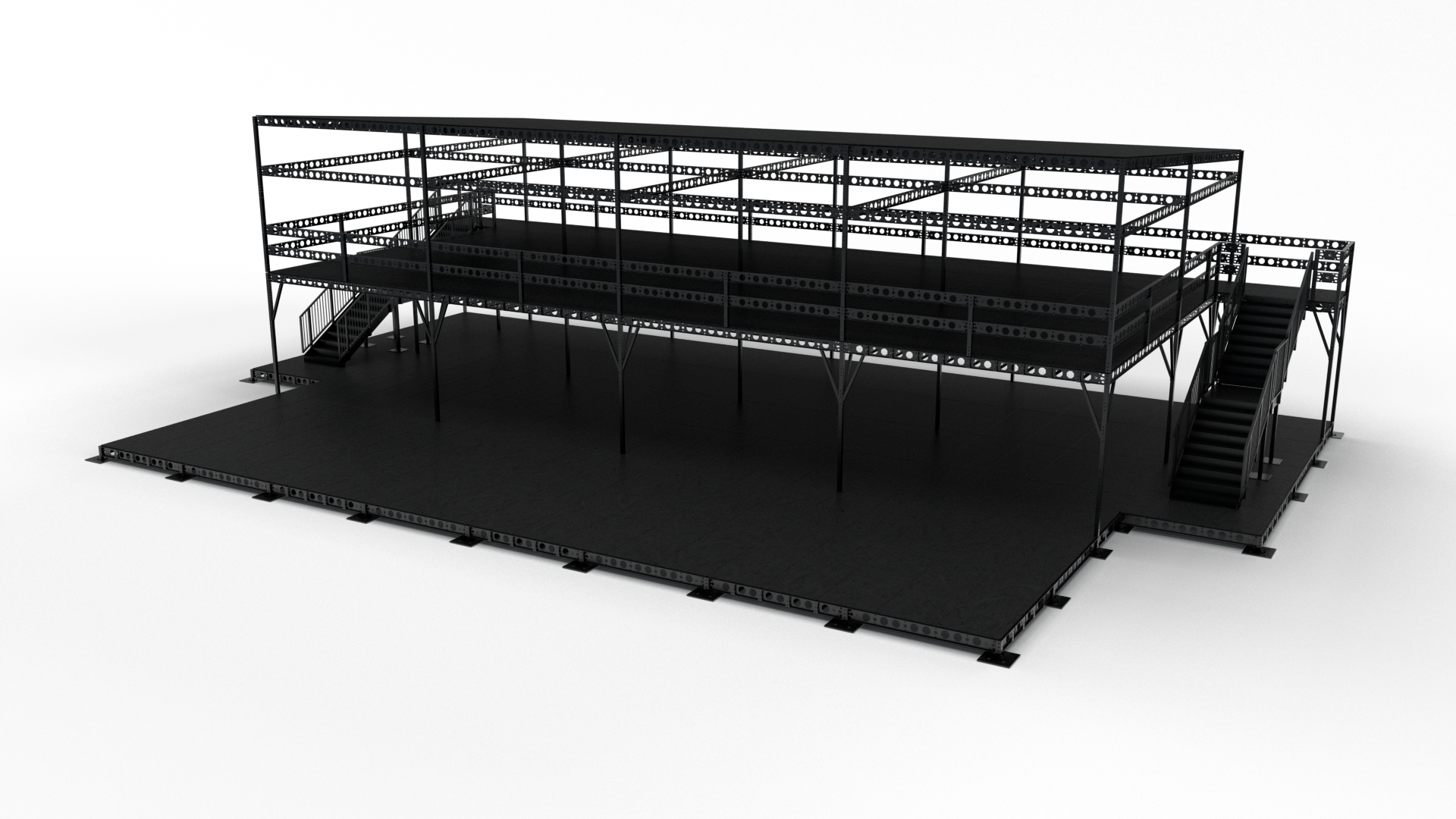

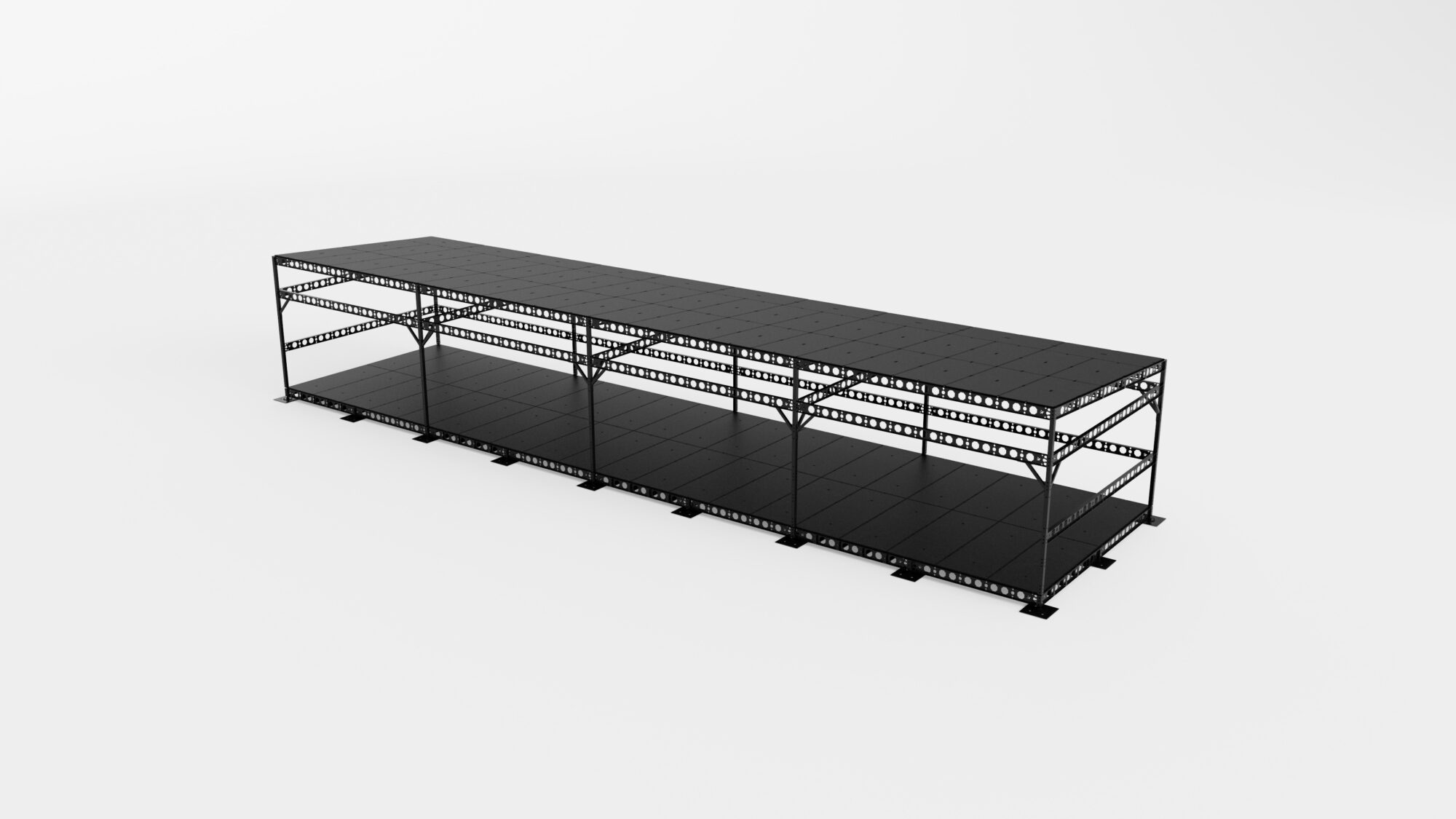

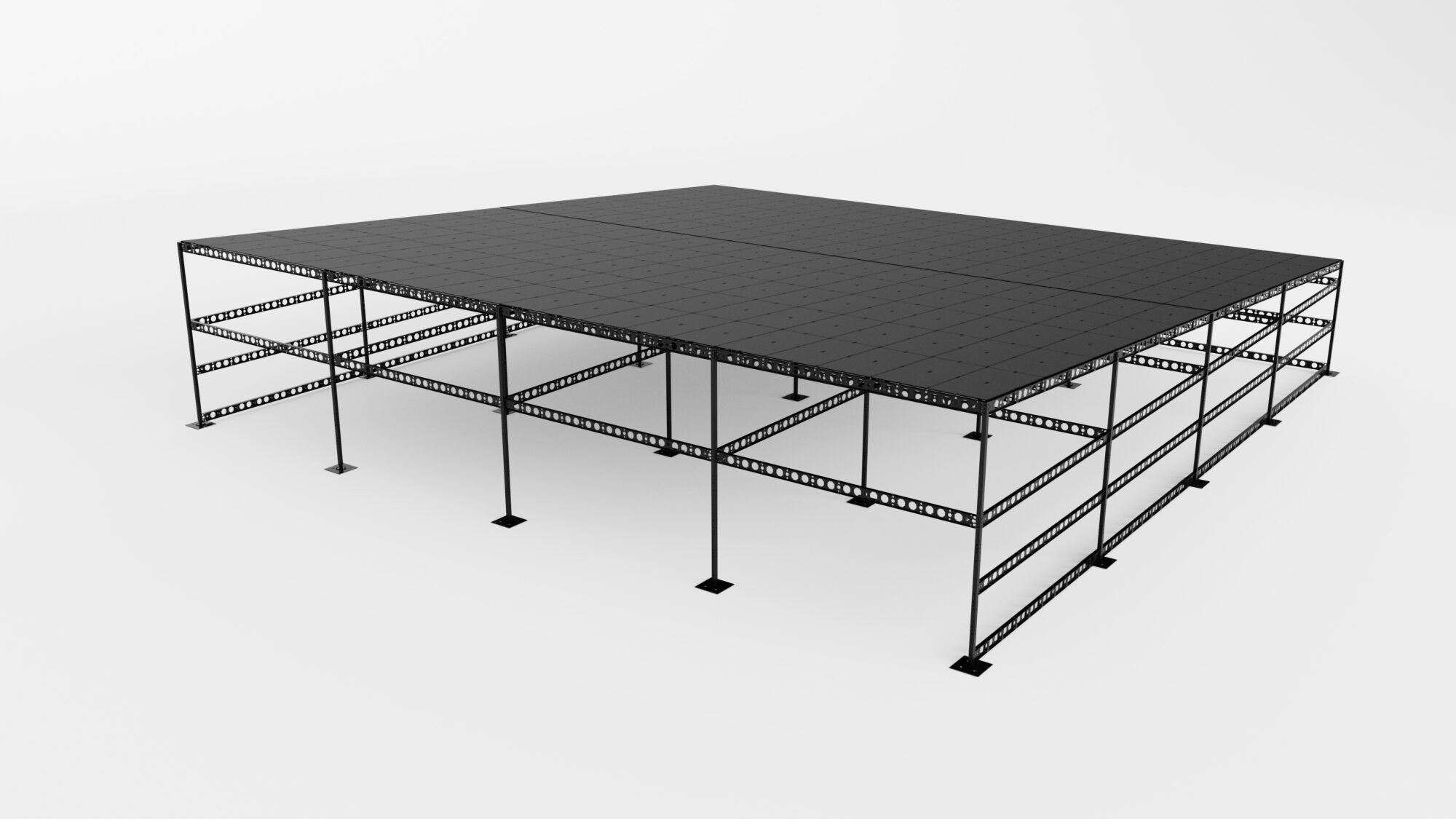

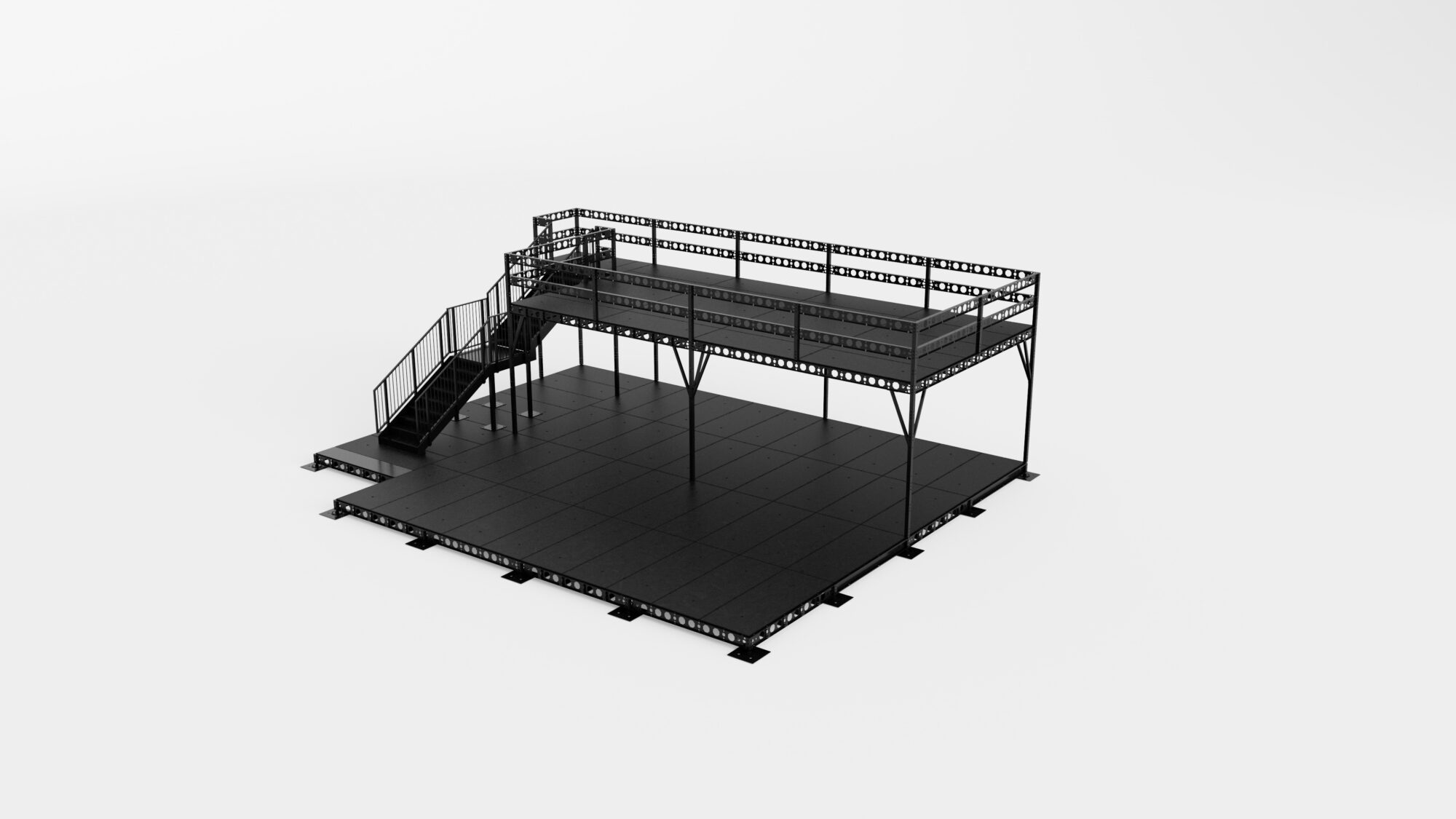

The modular nature of our system allows you to think bigger, bolder and more creatively with your ideas, we like to push boundaries at Halo. We can combine different modular structures or start from scratch to design fit for purpose structures that meet a wide range of briefs.

Structure Types

Modular Structures

Tap through a selection of our standard modular structures, we can combine models or design a bespoke creation

Technical Specifications FAQ

Full structural calculations are created for every structure we build, working in partnership with Symmetrys our structural engineers.

What size structure can we build?

Our standard beams start at 0.5m and increase in size by 500mm, all the way up to our largest span of 5.0m. Our specially designed modular structure system allows us to connect beams together in any configuration. Check out our standard structures. If you can't find what you're looking for there, we can design you a bespoke structure.

Can I have a structure that is not one of your standard structures?

Yes! We design and fabricate all of our own steel components in the UK, if you need a bespoke size structure that doesn’t fit our standard beam size, we can build it for you. Our R&D department works hand in hand with our structural engineers, so everything we design is signed off well before it's built. And as we manage all aspects of our fabrication, we can turn around bespoke components in short lead times.

Can I have a beam wider than 5 meters?

We are currently developing larger roof beams that can span up to 10m. This will allow us to build ground level structures that have a much wider span, without any columns getting in the way. When we build mezzanines, we have to retain some support underneath to reach the loads needed for crowds of people and equipment.

What KN loads can your mezzanine support?

With column supports at 2.5m intervals we regularly build mezzanines up to 5kN/m2 loads, which is the maximum required for viewing platforms and crowded areas. This allows for free flowing movements of people at your events. The most common mezzanine we build is for hospitality and lounge areas. These have column supports underneath at 5.0m intervals and are built to 3kN/m2 live loads.

Are your structures waterproof?

Our design registered angled beams provide the same strength of the primary and secondary beams in the frame but also give the gradient needed for water run off. We work with a number of materials but our tried and tested method for roof cover is 80mm thick, solid insulation panels for a strong fixed roof, used for semi permanent structures & longer hires. Or for shorter events or multi location tours, we secure 18mm roof boards to the beams and then slip PVC panels over the top, to make them weathertight.

What is the ceiling height?

Our standard columns are 3m, so when built, that gives you a floor to ceiling height of just under 2.8m on our mezzanine and hospitality forms. We have developed a pitched roof for our ground forms & fixed roof mezzanines, so the clearance above ranges from 2.8m up to 3.4m on these.

Can you build mezzanines or stages to any height?

Yes! We have a patented rivet nut system that allows us to build mezzanine levels and roof beams at almost any height. The rivet nuts allow multiple fixing points to be installed quickly and easily, so steel beams can be secured at any point and at any height for interior walls or cladding. This also allows for quick and easy adjustments onsite.

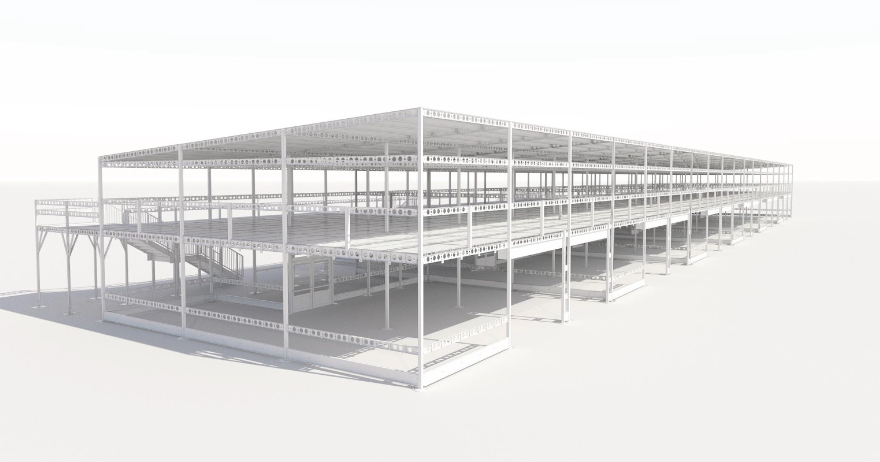

How many floors can you build with your mezzanine structures?

We have built 3 level mezzanines before with a fully operational ground floor garage, open plan first floor lounge with offices, and a fully decked second floor terrace. Our system allows us to add columns on top of columns to build multi level structures up to 7-9 meters high.

What ground conditions can you build on?

Most places! We’ve built on unlevel grass, sand, mud, tarmac and concrete. Our patented adjustable extension blocks and baseplates, allow every column that touches the ground to be micro adjusted to any height. This allows us to build completely level, within your chosen footprint.

Do you require additional ballast?

Not always. When ballast is needed due to strong winds or site specific requirements, we can stake into soft ground directly through our baseplates, like they do on marquees. On more long term structures, we can use resin anchors into hard standing and concrete to hold down the baseplates. If none of this is possible, we have developed many ways of utilising ballast weight under our decks to hide it, but if all else fails, concrete ballast can be brought in and secured directly to our columns and beams.

Can I fix scaffold or truss to your system?

You don't need to. Our steel beams are load bearing and have an M16 bolt hole every 500mm along the length. This provides multiple fixing points to the underside of the roof to secure lighting, sound equipment, cladding, directly from our beams, avoiding the need for expensive secondary truss or internal framework. Any extra loads are worked out at the design stage of a build, so all of the weights are incorporated into the design by our structural engineers.

Can I fix AV directly onto your frame?

Yes! We have developed an AV plate that bolts directly to the underside of our beams, providing a shelf for LED screens, cladding and branding panels. They are load bearing and provide the support needed and a smart finish from underneath. We also have an L cleat that secures from behind, so entire walls can be built and safely secured to our frame. With a dedicated R&D team. We can also develop bespoke cleats, clamps & specialist components, so whatever cladding or finish you have in mind, we can develop a solution through our Design Lab.

What are the handrail options for a mezzanine?

Our standard 2.5m beams can be used as handrail, if you want to highlight the steel ‘industrial’ look, or want to clad the front and back with branding or production panels. We have also developed a premium open handrail for hospitality events and viewing platforms, that allow us to infill the frames with perspex or strengthened glass. We have also developed a special handrail beam that allows us to bolt off the shelf posts and glazing systems directly into our beams.

What production and cladding options are available?

Any material you choose. We work with lightweight Steel I beams, specially developed to be small enough to lift but strong enough to construct a building. So we are using permanent building materials in a temporary, demountable way. This means you can clad the structure frame in sheet material, seamless branding, cladding panels, LED screens or constructed timber frames and production. Our preferred method is 60mm Solid Insulation Panels. We have developed our own clamping system, so we can quickly and easily slot the panels together, secure with hidden fixings and provide a fully weatherproof structure within a matter of hours.

How do you comply with current regulations?

We take the methods and safe practices from the construction industry and blend them with the fast approach to build and design in the events world. Everything we do is done with the full support and sign off of our structural engineers. We have over 13 years experience of developing ideas into realistic structures that meet your needs but are designed to the highest EU standards. Our system has been approved by the TUV governing body in Germany and all our structural calcs are measured against permanent building regulations.